Interfacial assembly and microcapsules

I. Breakup dynamics of soft microcapsules

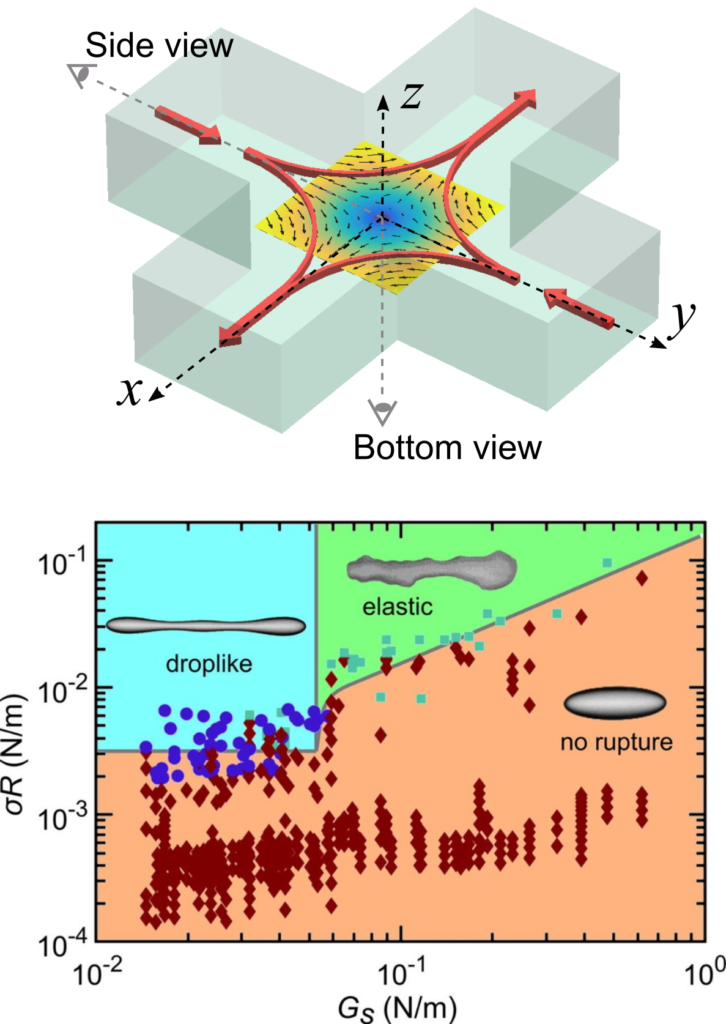

The controlled rupture of a core-shell capsule and the timely release of encapsulated materials are essential steps of the efficient design of such carriers. The mechanical and physico-chemical properties of their shells (or membranes) mainly govern the evolution of such systems under stress and notably the link between the dynamics of rupture and the mechanical properties. In this work, we used an extensional flow cell to deform the soft microcapsules and observed two different rupture regimes depending on the rheological properties of the capsule membrane: droplike and elastic ruptures.

Collaborators: Revaz Chachanidze (Univ. Grenoble Alpes), Marc Jaeger (Centrale Marseille), Marc Leonetti (CNRS Marseille)

Papers: (1) Mechanical characterization of core-shell microcapsules. Comptes Rendus Mécanique, 2023, 351 (S2), 1-20.

(2) Breakups of Chitosan microcapsules in extensional flow. Journal of Colloid and Interface Science 629 (2023):

445-454.

II. Interfacial assembly

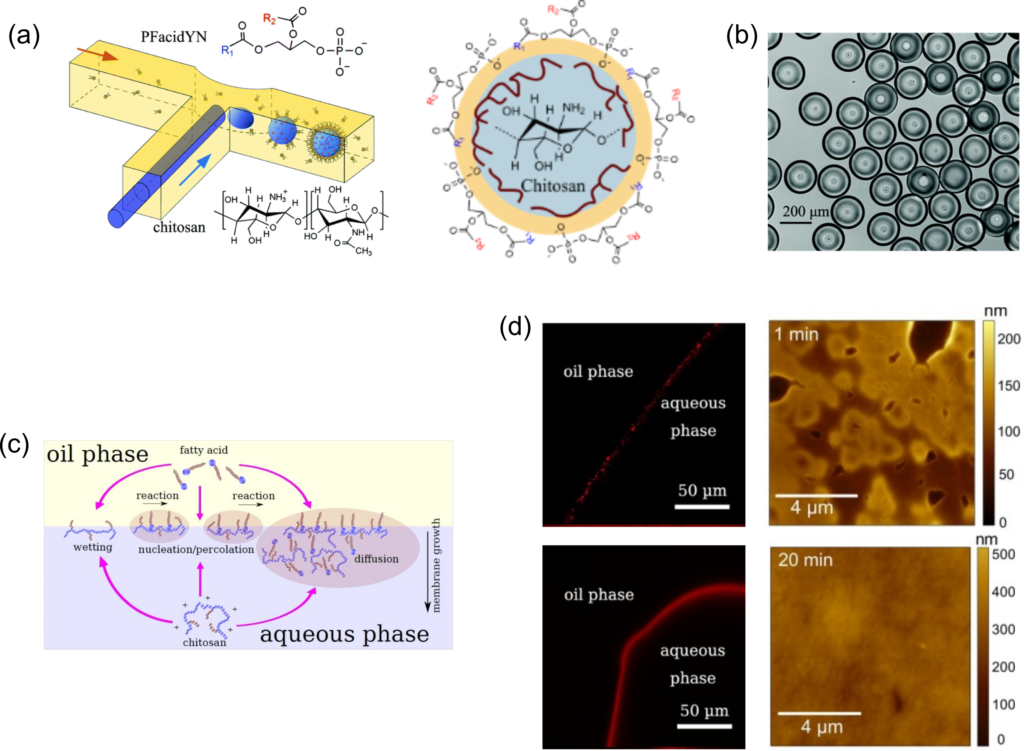

Thin membranes are essential in biological processes, such as controlling the mass exchange or achieving specific functions for cellular activities, as well as in many industrial applications, such as encapsulation for drug delivery. In practice, assembling the membranes with controllable properties is challenging. Controlling the assembly of polyelectrolytes and surfactant at interfaces offers new ways to fabricate soft materials with specific physical properties. However, there is not much knowledge of the relationships between the kinetics of interfacial assembly, structural and rheological properties of such interfaces.

Here, I focused on the kinetics at water-oil interface of the assembly of a positively charged polyelectrolyte with an anionic fatty acid. Our findings revealed that the interfacial complexation was a multi-step process. At short time-scale, the interface was fluid and made of heterogeneous patches. At a ‘gelation’ time, the surface elastic modulus and the correlation between speckles increased sharply meaning that the patches percolated. Confocal microscopy and AFM confirmed this picture (see the Figure).

Our work here brings new understanding on the interfacial complexation that dominates and control the properties of interfaces. It paves a new way for the design of new materials by structure control.

Collaborators: Revaz Chachanidze (Univ. Grenoble Alpes), Clément de Loubens (CNRS Grenoble), Marc Jaeger (Centrale Marseille), Marc Leonetti (CNRS Marseille)

Papers: (1) Interfacial rheological properties of self-assembling biopolymer microcapsules. Soft Matter, 2017, 13(36), 6208-6217.

(2) Structural characterization of the interfacial self-assembly of chitosan with oppositely charged surfactant. Journal of Colloid and Interface Science 616 (2022): 911-920.

(3) Membrane emulsification for the production of suspensions of uniform microcapsules with tunable mechanical properties. Chemical Engineering Science (2021) 237, 116567

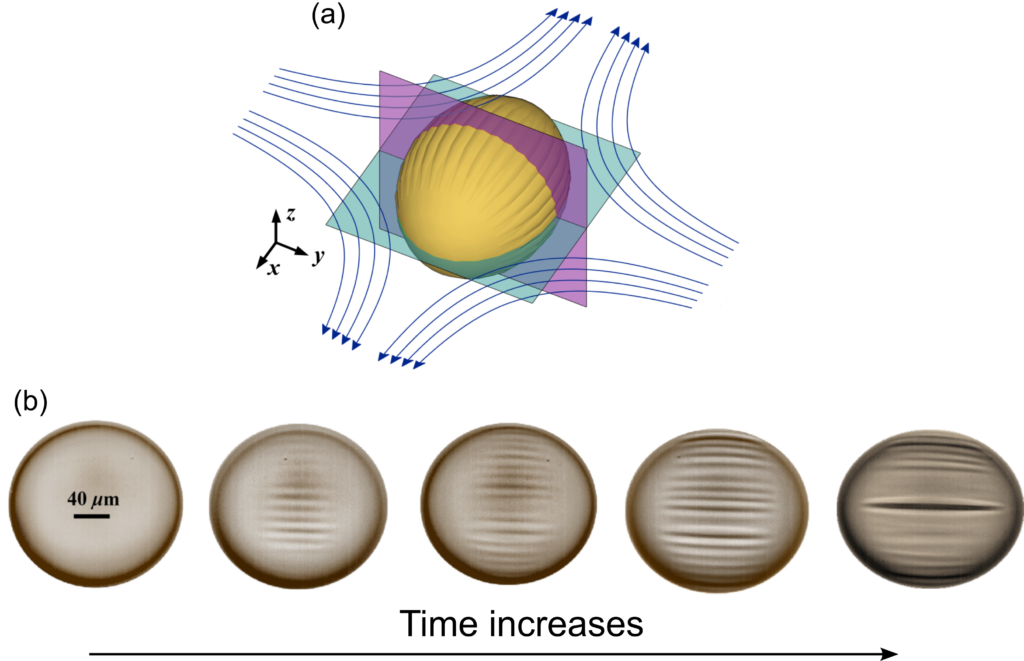

III. Wrinkling instability of soft microcapsules

Thin membrane are more prone to exhibiting out-of-plan deformation instead of in-plane deformation as it costs a lower energy in bending, when the membrane is under compression. In the extensional flow, the microcapsule was stretched along the direction of the flow going to outlets of the channel, while it was compressed in the perpendicular direction. When the flow stress is above the critical value, the surface of microcapsule becomes unstable where the wrinkles appear. The length of the wrinkles increases with time and reaches an temporally equilibrium state when the deformation of the capsule is stable. However, with long time observation, the wrinkles can transform to a second instability mode, folding, where locally the wrinkles merge while vanishing the neighbors.

Collaborators: Marc Jaeger (Centrale Marseille), Marc Leonetti (CNRS Marseille)